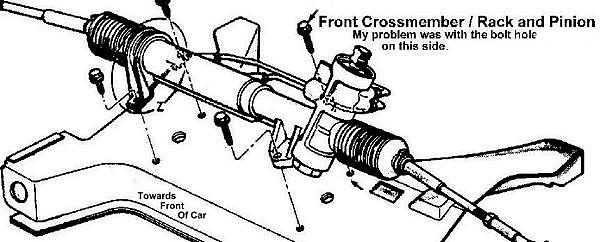

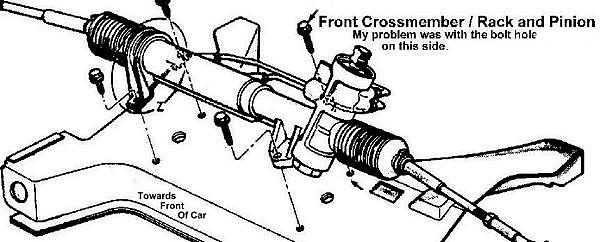

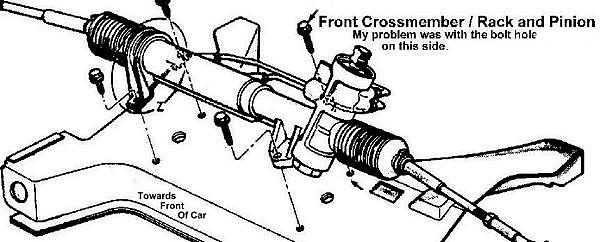

The problem is that that bolts are threaded directly into the crossmember

without any kind of reinforcement. Over time the bolt holes are elongated

to an egg or oval shape causing the bolts and steering to become loose.

When I got the car the driver side bolts had been worked on, but the passenger

side seemed ok. The front one was holding but the rear one wasn't

done so well because the design of the crossmember requires each one be

done differently. Near the rear bolt (on the rear side of the crossmember)

someone had blow torched a hole to get inside the crossmember then had

screwed a flat, rectangular, nut on the bolt. I think they forgot

the finish the job by welding this pressure plate bolt to the crossmember.

My temp fix was to tighten the bolt every couple

of weeks. After the steering pump went it took a lot of stress off

this bolt and I only had to tighten it once every month. Eventually

it started to hold better, but I still don't trust it compleatly.

What I plan to do is tighten it down as well as I possibly can without

striping it (already done) then weld the pressure plate/nut that the bolt

screws into (on the inside of the crossmember) to the crossmember, then

put an additional locking nut on the end of the bolt (The other hole on

the same side had already been drilled all the way through with a longer

bolt put threw it then tightened down with a nut and locking washer).

After all that I'll just have to pray it stays well enough until I can

get into some serious front end R&R at which time I may consider replacing

the crossmember.

Back.